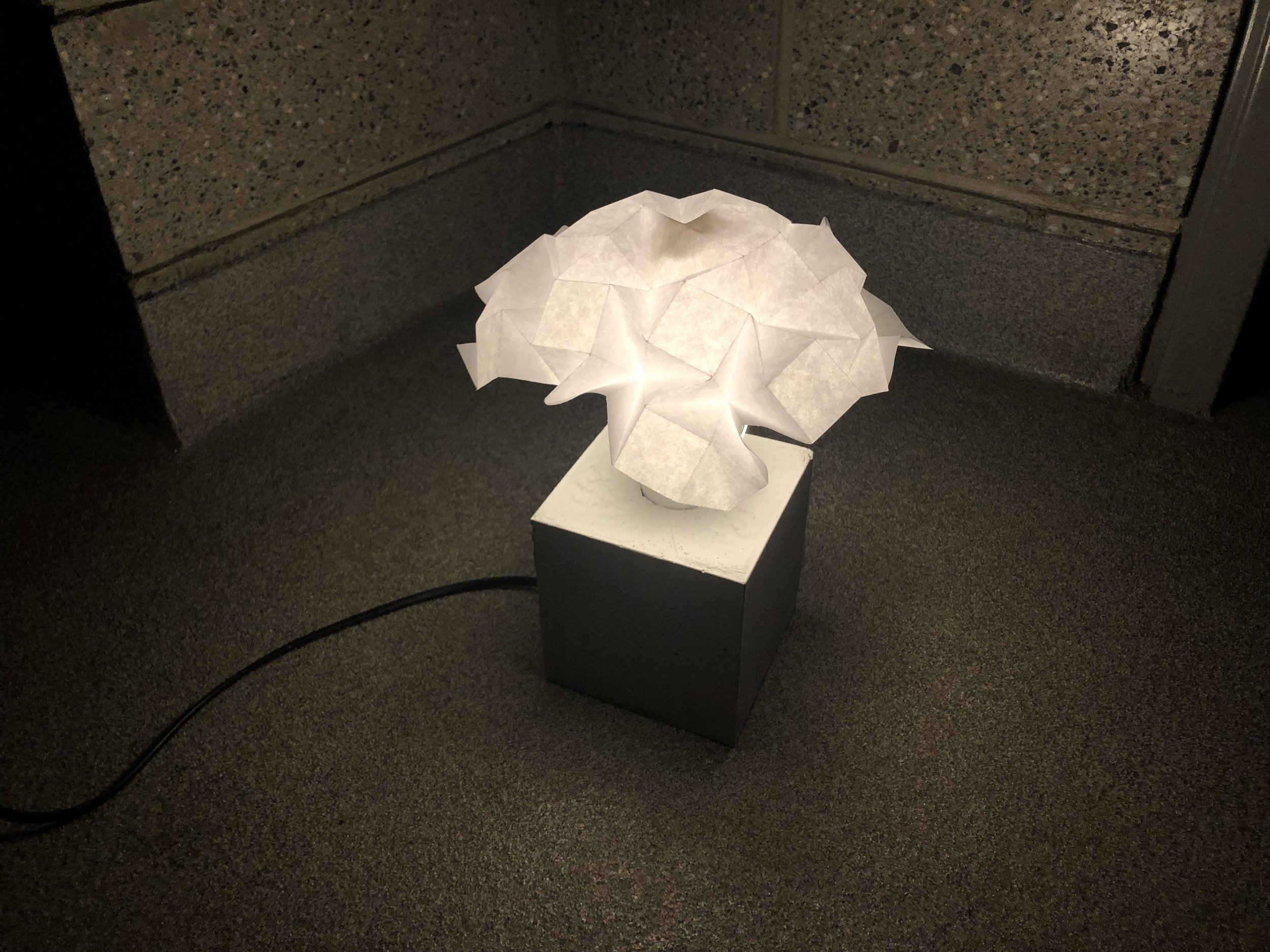

Cement Lamp

The Challenge

Create a community design workshop centered around a cement project

The result

A DIY lamp that teaches participants about 3D printing and working with cement

The details

Timeline: 2 weeks

Workshop location: Yale Center for Engineering Innovation and Design

Skills used: 3D CAD modeling, 3D printing, rapid prototyping, teaching

The workshop

Participants created molds, mixed and poured Rockite cement bases, and crafted acrylic and paper lamp shades during this free two-hour workshop. The workshop was popular, engaging, and inexpensive to host, and will be run again in future years.

Design process

ideation

I drew inspiration from modern concrete buildings on campus, particularly Beinecke library. I chose a simple, cube-shaped base for the lamp for its clean look and ease of mold construction. A void in the center of the cube, molded around a custom 3D printed insert, holds the lightbulb and its power cord.

Gordon Bunshaft’s Beinecke Rare Book and Manuscript Library on Yale University’s campus

Initial sketches

Initial prototype design

Prototyping

I prototyped both a 4- and 5-inch cube base, and decided that the 4-inch option was better because it was lighter and required less material, but still looked sturdy and substantial. I also tested various paper lampshade to determine the ideal diameter of the lampshade and height of the lightbulb above the base.

This lampshade was too narrow, and a harsh line seen from the outside indicated where the lightbulb began and ended.

This lampshade was better, but the elevated position of the lightbulb relative to the base created a dark zone on the bottom of the shade.

An elevated lamp shade diffused the illumination from the lightbulb nicely, but exposed the unsightly power cord attachment.

A 5” diameter lampshade proved ideal when paired with a low lightbulb height.